SAGDesign Testing

The flagship SAGDesign test is the most accurate grindability test available. The SAGDesign test measures the pinion energy to grind ore from 80% passing 152 mm to 80% passing 1.7 mm (WSDT). The 2nd stage of the test measures the Bond Ball Mill Work Index on SAG ground ore, Sd-BWI. SAGDesign ore feed is prepared from a minimum of 10 kg of split or whole diamond drill core pieces or run of mine ore, by stage crushing the ore in a jaw crusher to 80% passing 19 mm. The crushed ore is then ground in a SAGDesign SAG mill (489 mm inside diameter x 163 mm EGL), seen here, that operates with parameters similar to commercial SAG mills (26% total charge; 11% steel load, 15% ore load; and rotation at 76% of critical speed).

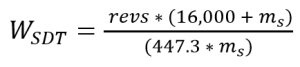

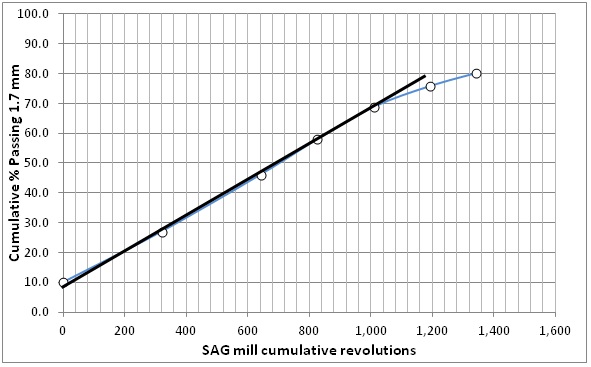

The calculated cumulative mill revolutions to 80% passing 1.7 mm is used together with the mass of the SAG mill charge to compute the SAG mill specific pinion energy, as seen below. The process to determine the revolutions is done in cycles, with the -1.7 mm material (fines) removed from the mill after each cycle up to 60% passing 1.7 mm. After the first grinding target is reached (i.e 60% -1.7 mm), both the fine and coarse materials are returned to the mill for the remainder of the SAG mill grinding cycles to reach the 80% -1.7 mm test end point. A typical SAGDesign SAG test grind curve is illustrated below.

Where:

| WSDT | = | AG/SAG pinion energy from F80 152.4 mm to T80 1.7 mm (kWh/t), subscript notes the test |

| Revs | = | Cumulative number of SAG test mill revolutions to T80 1.7 mm, measured by SDT |

| ms | = | SAG mill feed sample mass (g) |

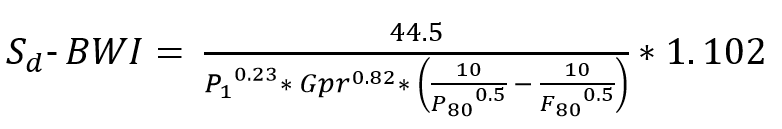

The second stage of the SAGDesign test measures the Bond ball mill work index on SAG ground ore that has been crushed to 100% passing 3.35 mm. The ball mill work index is determined from Bond’s Third Theory of Comminution:

Where:

|

F80 |

= |

80% passing of feed size (µm) |

|

P80 |

= |

80% passing of product size (µm) |

|

P1 |

= |

Closing screen (µm) |

|

Gpr |

= |

Grams per revolution, average of last 3 Bond cycles |

The SAG mill pinion energy, WSDT (kWh/t) and SAG discharge Bond ball mill work index, Sd-BWI (kWh/t), are then used to calculate the total energy to grind the ore from 80% passing 152 mm to 80% passing the client specified final product size P80. This information, along with the ore specific gravity, is used to calculate necessary mill sizes and motor power in industrial applications. SAGDesign testing implements first principle technologies developed by Fred C. Bond to design grinding circuits.

Typically, Starkey & Associates recommends SAG mill circuits followed by a ball mill(s) working in series with the SAG mill. The quantity of mills or pebble crushers recommended is dependent upon the ore hardness, design plant throughput, and final product size desired for ideal liberation.

SAGDesgin testing is also used in benchmarking projects where a total energy predicted by the test is compared to the actual power draw observed in the plant. Historically, the accuracy of the tests is within +/- 10%. S&A’s paper presented at Gecemin’s Procemin 2012 conference in Santiago, Chile, gives more information on this matter.

If you have more questions about the SAGDesign testing procedure or deliverables, or if you would like to request a quote or proposal, please contact us. Furthermore, S&A’s publications provide a more in depth evaluation of our products and services.

Test Work Validation

Starkey & Associates employees review all SAGDesign and variability grinding tests done in every laboratory to ensure that the quality and accuracy of the work done meets quality control standards. S&A provides the SAGDesign test procedures and oversees the test work results for every commercial laboratory offering SAGDesign testing services.

Eight of the ten SAGDesign laboratories were benchmarked for accuracy of the SAGDesign test in late 2011. WSDT results were within +/- 5% of the average while Bond BWi results for the same tests were within +/- 10% of the average BWi for all eight labs. More information on this study can be found here.